Safety at Abbey Boilers will always be our first priority . Throughout the pandemic we as an organisation have taken swift and immediate action to keep our customers and staff as safe as possible.

The changes that have been implemented were significant to our business at the start of the pandemic, both in terms of our operations and how our engineers operate in the field. We have been maintaining social distancing in our offices with reduced staff and levels of strict hygiene have been adhered to by our engineers on the roads who have been issued with correct and sufficient PPE.

We will continue this while we carry on emergency work for customers across the South East and West Sussex, including priority jobs for key worker staff.

We are slowly starting to see signs of companies planning gradual return to work, and slow introduction of employees back into the workplace. A gradual return will help maintain social distancing in early days and give companies enough time to require employees to fill out health assessments and get tested if necessary. Rest assured meticulous planning is in place and steps are being taken to ensure safety of both customers and employees.

Some of the big housebuilding companies like Taylor Wimpey will be starting to build again shortly and car firms such as Nissan and Jaguar Land Rover are preparing to resume production in their factories.

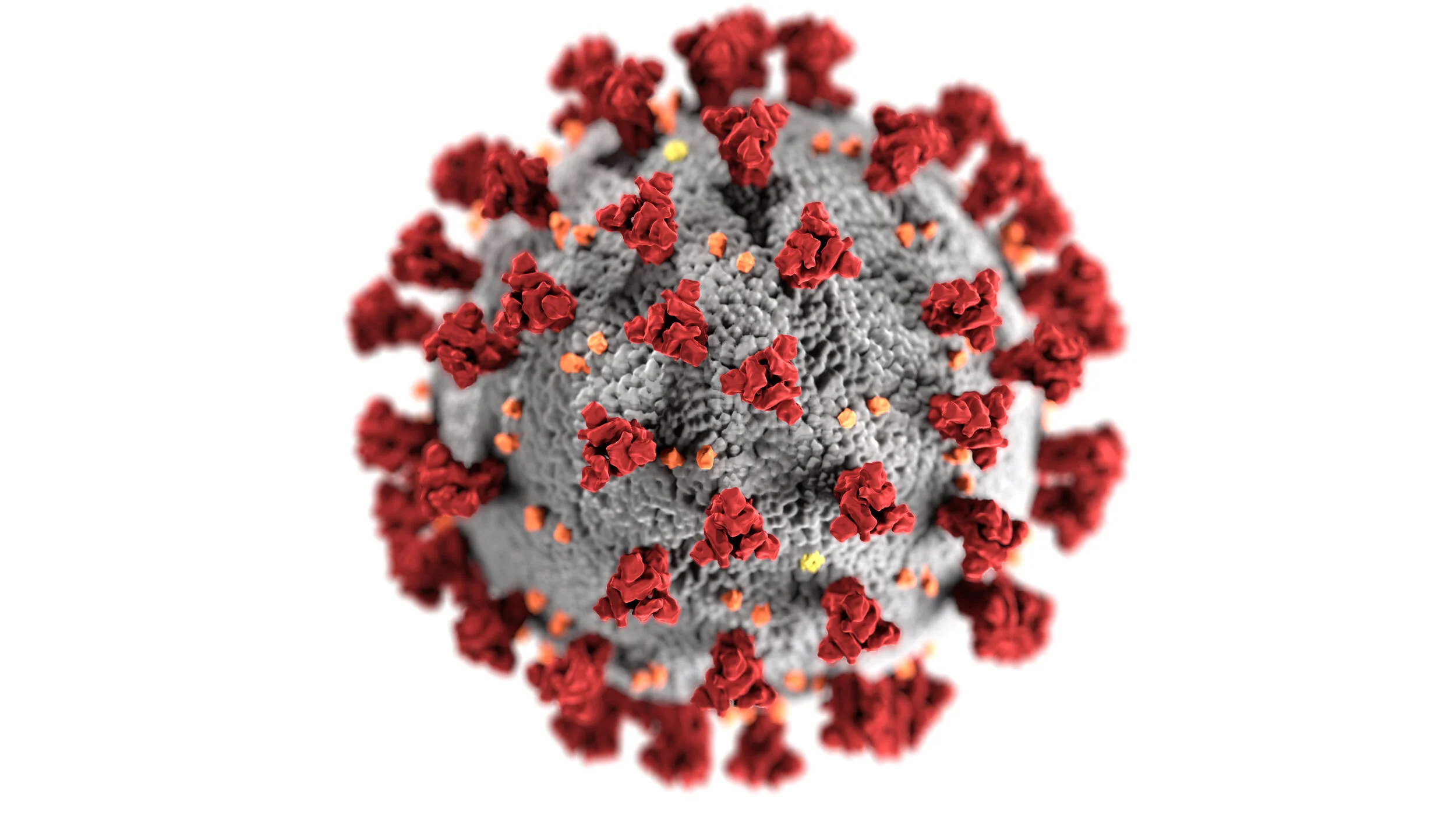

These are all positive signs for the economy and our amazing country. This does not mean battle against COVID-19, which is by no means close to ending yet.

The way we live and work will be quite different from what we are used to for many months to come or even longer. The Chief Medical Officer, Professor Chris Whitty said during one of the recent government daily press conferences that social distancing will need to be in place for ‘some considerable time’.

If that is the case, the country and its business community have to be able to adapt. The health of the nation is, undoubtedly, the first priority, but having an active economy filled with businesses that create employment, follows a close second.

We know the lockdown as it is now cannot continue for the long term and there are reports that the pandemic has reached its peak and has levelled off, but the same time, we can’t risk ruining the hard work we have all put in to stop the virus spreading further with a second spike.

Therefore, we have to adapt and evolve, which is something entrepreneurial businesses in the UK have been doing for generations as we have at Abbey Boilers when we started fixing our first boiler all those years ago.

As a business that provides an essential service from workers that cannot work from home, we changed quickly. Times like this spur innovation and we implemented new ways of working that would keep our people safe, but also our customers as the majority of the time the only way we can carry out our work is to enter their homes.

We will continue to apply these processes for the foreseeable future as we return to providing more than emergency call out jobs.

We too will be looking forward to get back to normal working conditions in people’s homes and business premises as before.

But until then we have to together as a country beat this, only together can this be achieved.

Stay Safe!

Abbey Boilers